How to fix mismatch between I/C quantity and Lot/Serial quantity of an item if there is a variance on the I/C Serial/Lot Number Quantity on Hand Report?

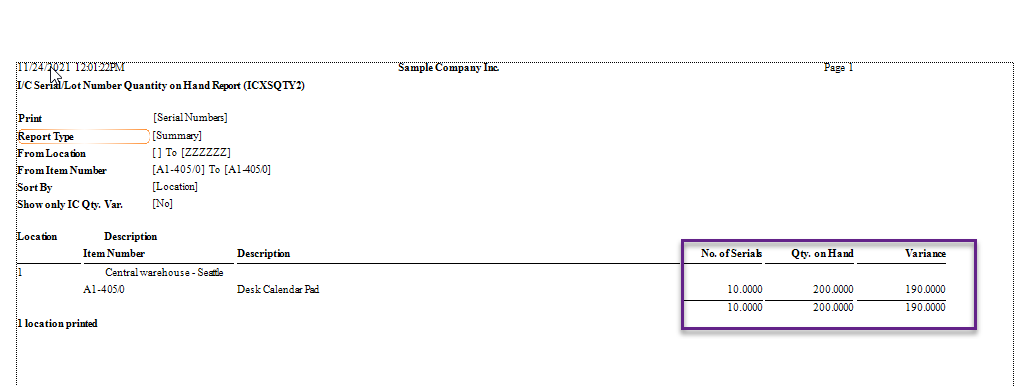

Below is an example in our sample data for this item, A1-405/0 at location 1. As you can see the Qty. on Hand for this item is 200 EA but the No. of Serials is only 10 EA. There is a variance of 190 EA.

In most cases/ businesses, the Quantity on Hand of an item should be the same as the Number of Serials of an item. This also applies to an item which is lotted as well.

There are some common reasons that cause the mismatch in this situation:

- Check the option for “Serial Number” or “Lot Number” in I/C Items after the items are in use. That means there were transactions posted against the I/C item before you mark the items to be serialized or lotted.

- The option “Allow Serial/Lot Quantity to be different from the Quantity in the Entries” is checked in Serials tab in I/C Options to entries to be saved even if the number of assigned serial numbers is less than the quantity of serialized units that you are working with.

In this case, assuming the Quantity on Hand of this item is correct, if the users want to fix the mismatch for the Number of Serials of this item only, they can use Serial/Lot Reconciliation in I/C Periodic Processing folder.

In Serial/Lot Reconciliation:

- Select the correct Transaction Type. There are 4 different transaction types:

- Use Receipt to add serial numbers or lot numbers to match the number of items on hand.

- Use Shipment to remove serial numbers or lot numbers to match the number of items you have on hand.

- Use OE Invoice to change the serial numbers or lot numbers assigned when items were sold, or to add the numbers if they were not assigned. This option allows you to link it to OE invoice number in Apply to Document

- Use PO Invoice to change the serial numbers or lot numbers assigned when items were received from a vendor, or to add the numbers if they were not assigned. This option allows you to link it to PO invoice number in Apply to Document

- In this scenario, we will use Receipt as the Transaction Type because you want to match the number of serial numbers to the quantity on hand of this item.

- Enter or select Item Number in the finder in Item Number In this case, enter “Al-405/0” in Item Number field.

- Enter or select Location in Location Enter “1” in Location field.

- Enter the Stock Date in Stock Date Specify the date that the item with serial or lot numbers were received into the inventory. The default date is the session date.

- Enter the correct Quantity and Cost of for the serial numbers for this item. Note: the Cost field refers to the Unit Cost of the Serial number.

- Click either “Add” or “Auto Generate” to generate the serial numbers.

- At the bottom of the screen, the Serial Nos. Required should be equal to the Generated. In this case, both fields should be “190”.

- Click “Post” to post the transaction.

Run Day End Processing in I/C Periodic Processing folder if “Costs Items During” option is set to “Day End Processing” in I/C Options in I/C Setup folder.

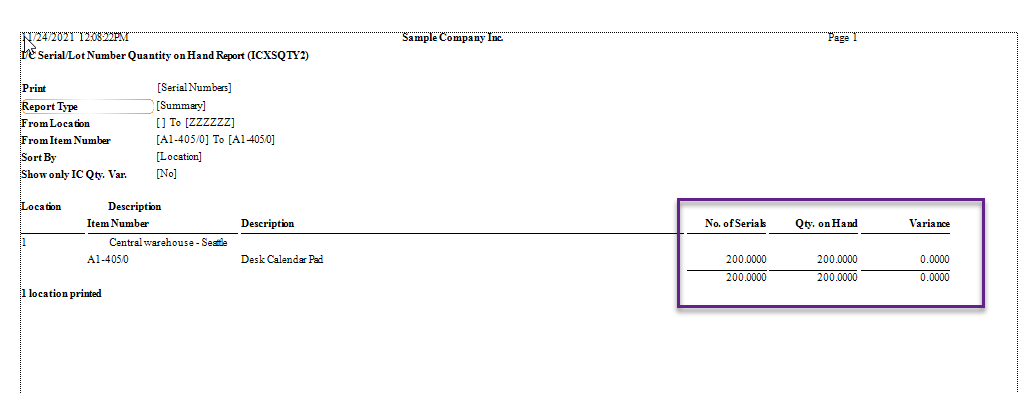

- Print the I/C Serial/Lot Number Quantity on Hand Report again for this item. There should be no mismatch in this case between the number of serials and the Quantity on Hand of this item.

As you can see, there is no more variance between the No. of Serials and Qty. on Hand and the cost are also matched.

We recommend users to make a backup of the data before performing the transaction. We hope this information helps to fix the mismatch between I/C Quantity on hand and Serial Numbers/Lot Numbers.