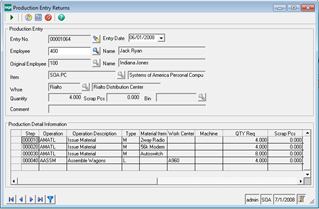

Production Entry Returns

Light Manufacturing and Advanced Kitting customers who use the Production Entry task can process Production Entry Returns despite the fact that they cannot maintain or manually create work orders.

Work order transactions processed behind the scenes will be returned in the same manner as Work Order Progress Returns with variances posted against the original labor transaction. The user will; however, select the original Production Entry transaction as opposed to the Work Order transaction from the look-up screen.

All material and labor transactions posted against the production entry will be reversed. There will be no returns or postings to WIP.

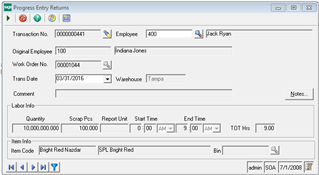

Progress Entry Return

Progress Entry Return is the task used to return finished goods inventory back to the work order that originally produced inventory quantities.

Returns result in a reduction of inventory quantities (for make items) as well as costs at the then current costing amount which may be different than the original amount (e.g., the average cost for the original progress transaction for a raw material may have been $1.05 while the current average cost for the item is $1.10). A variance may be reported where current costs do not match original costs.

Clicking the Proceed button on the toolbar returns the inventory quantities and inventory costs to work in process (WIP). For example, entering an incorrect work order for a progress transaction, entering an incorrect finished good quantity for a work order progress transaction, or not entering a manual material or labor transactions prior to posting the progress transaction. Backflushed material and labor transactions associated with the labor progress transaction will be automatically reversed.