In this blog I would like to discuss a scenario where a purchase reorder product with a safety stock and what happens when the safety stock is increased.

For example, a bought, manufactured and sold product is set to have a safety stock. MRP will generate a POS for the safety stock. Then the POS is converted into a POF with an expected receipt date in the future and the safety stock is also increased.

How to get the MRP to generate a POS for the difference in safety stock?

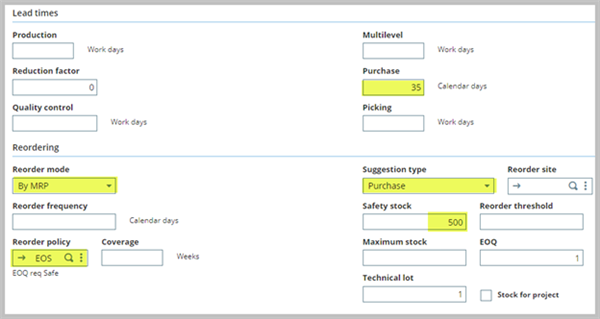

Create a product-site record with a safety stock of 500 + a purchase LT 35 days.

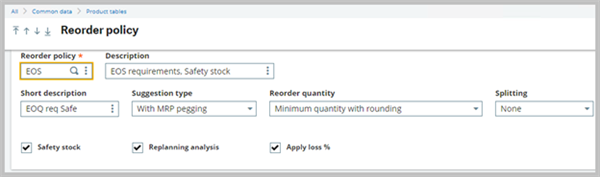

Reorder policy

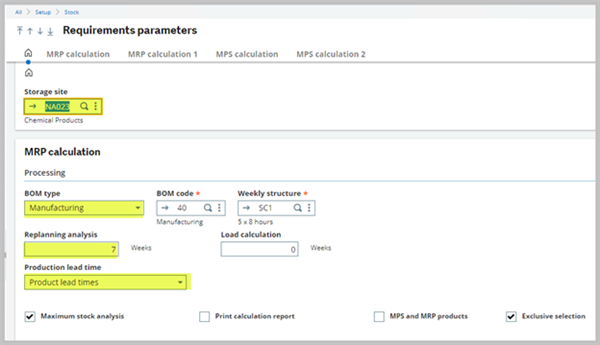

Setup the stock requirements parameters

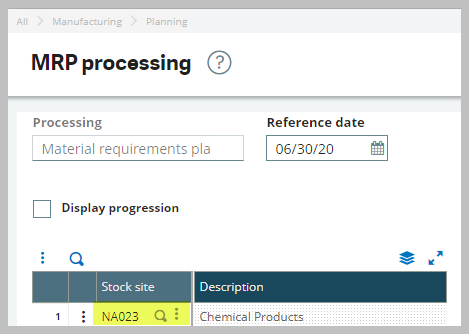

Run MRP

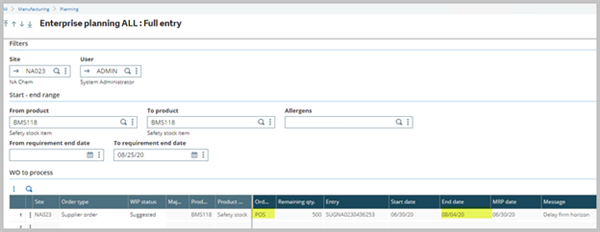

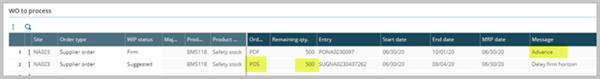

In Enterprise planning workbench, we can see the POS for the safety stock of 500. Additionally, we see the requirement date 08/04/20 includes the LT of 35 set on the product-site record.

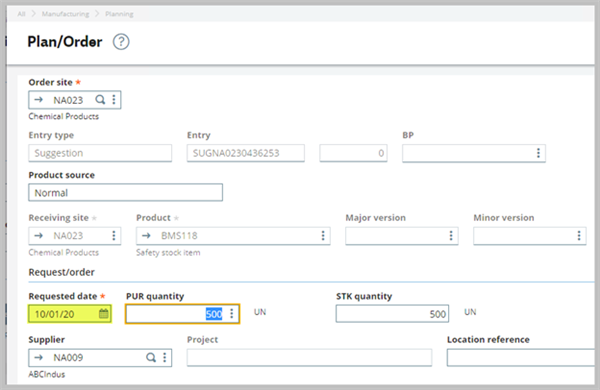

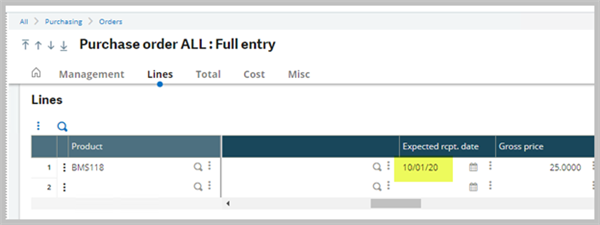

Convert the POS into a POF with an expected receipt date in the future 10/01/20.

PO

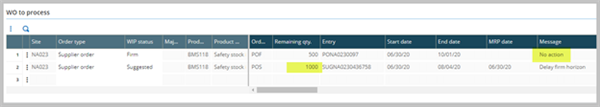

Under product-site record increase the safety stock from 500 to 1000 and run MRP.

Notice, MRP generates a new POS for the new safety stock and ignores the existing POF.

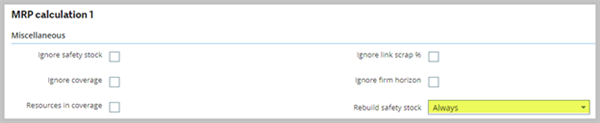

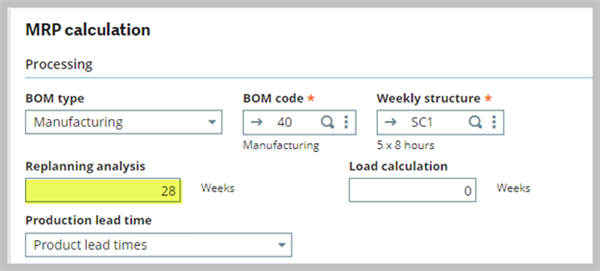

To fix this, adjust the replanning analysis setup to cover the extended requirement date of the POF

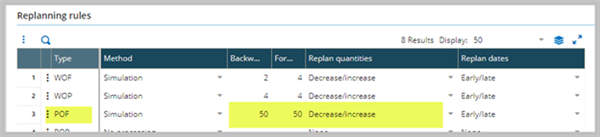

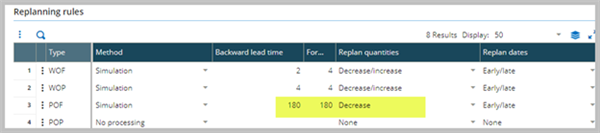

And the replanning rules for the following POF, Backward and forward LT and the replan quantities

After running MRP, the new POS is for the difference between the initial safety stock and the new one. Plus, MRP message for the firm PO indicates to ‘Advance’ it.

I hope this simple scenario might have helped you to understand the various settings that are present when generating suggestions.