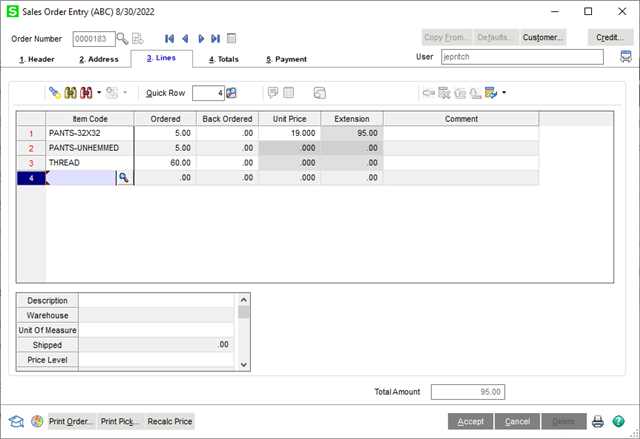

Trying to figure out the best way to process SO lines with uniform pants on them that we stock. The issue is we inventory pants unhemmed, that way when a customer orders a 32x32 we hem the pant to the 32 inseam. So technically we take out of the unhemmed inventory and create a new item code with the 32x32. We also might have some 32x32 in inventory (from canceled orders) and we get an order for a 32x30, ideally we would want to pull a 32x30 but if there's no inventory I would want to pull the 32x32 and hem it 2" to make a 32x30.

Would this be a situation for a lookup table? Or alias item codes, I knew we would have an issue with this situation when we try to get everything on inventory correctly. Right now it is a manual process, the order is entered as a 32x32 and when the picker goes to pick the pant, they look on the shelf and pick either the exact size or one with a longer inseam to hem. Nothing in Sage is accurate on inventory levels right now.