Hello, everyone!

We are facing an issue during the production scheduler implementation. The customer uses products characteristics to optimize the set-up time. Let’s say it is 5 hours long for a complete machine set-up, then to change from a product with diameter 5 to another with diameter 6 it takes only 1 hour. How could we set it up in the system?

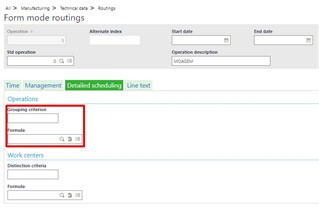

We have considered using the formula field to insert the criteria, but we are not sure it would work with the production scheduler.

Has anyone had this problem? Would you suggest how could we solve it?