We can assign a default location at the work center level and use that location as a default location in stock transactions.

For example, WO material tracking transactions.

To issue out material from a work center location we need to first, assign a location to the work center, then this work center will be used when a material is attached to an operation and its allocation rule filters on a local location.

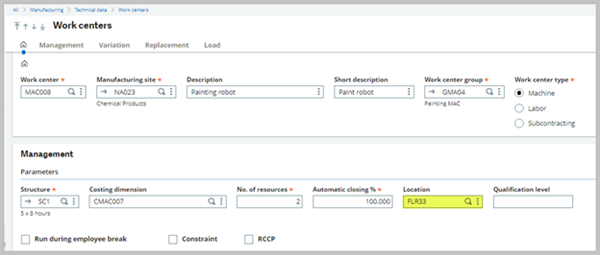

1. In Manufacturing, Technical data, Work centers select the work center and assign a location.

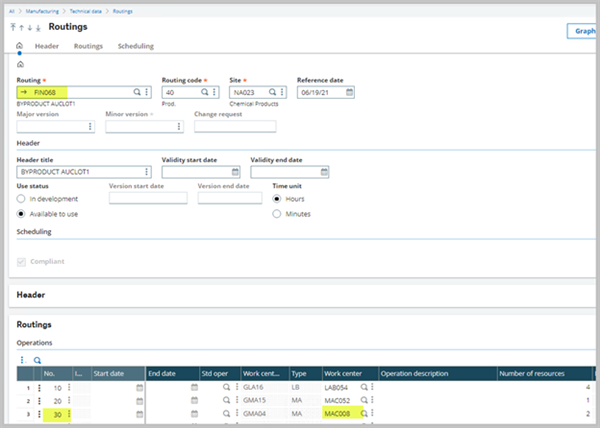

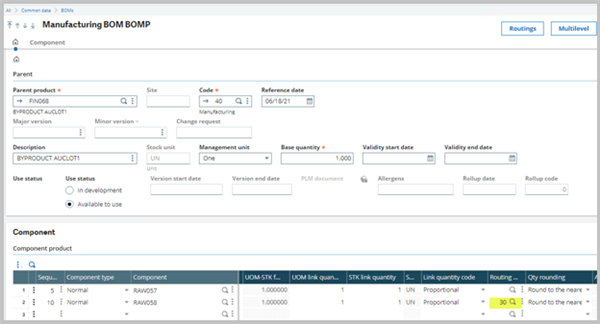

- This work center is linked to a routing and that routing is associated to a production BOM.

2. Select the component line on the production BOM and enter the routing operation number under ‘Routing operation’ column.

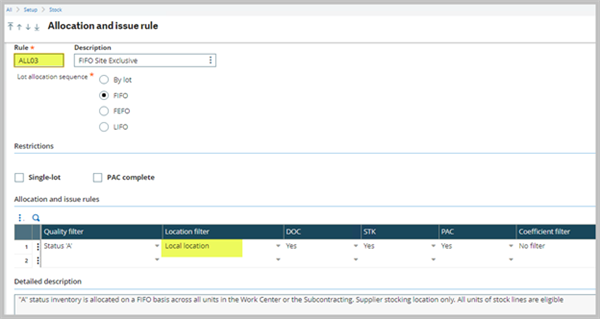

3. Finally, under product category, issue flow, issue rules, material consumption, select an ‘allocation and issue rule’ where the location filter is set to ‘Local location’.

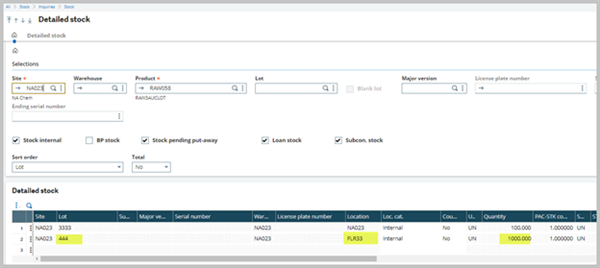

To illustrate this process, material RAW058 is available in two locations.

a. Lot 3333, Qty 100 in location NA023.

b. Lot 444, Qty 1000 in location FLR33.

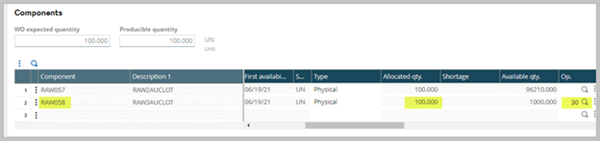

1. Generate a WO with a released quantity of 100 and allocate it globally.

- WO component RAW058 shows the operation 30 is associated with it.

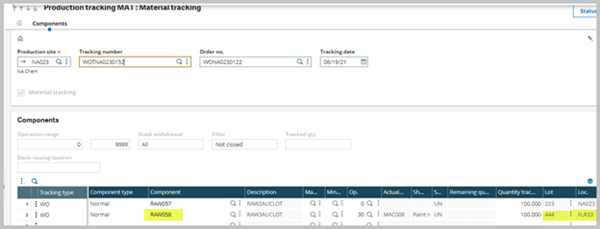

2. Generate a material tracking and check the location defaulted on the material RAW058.

- There you have it, the material location gets defaulted from the work center location.

-

Brian Blasius

-

Cancel

-

Vote Up

0

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

-

Joel Singam

in reply to Brian Blasius

-

Cancel

-

Vote Up

0

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

Comment-

Joel Singam

in reply to Brian Blasius

-

Cancel

-

Vote Up

0

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

Children