In Manufacturing, Planning, Orders, when creating a work order, there is a Status field that is found on the WO header tab. This field changes based on the work order tracking situation. The Status field comes from Local menu 339 (Work order situation), and it changes based on the work order progress.

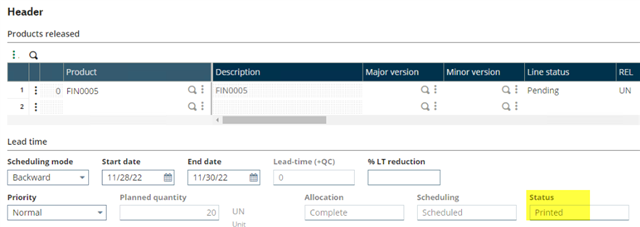

When the work order is created, the status is Pending.

When the work order is printed, it changes to Printed.

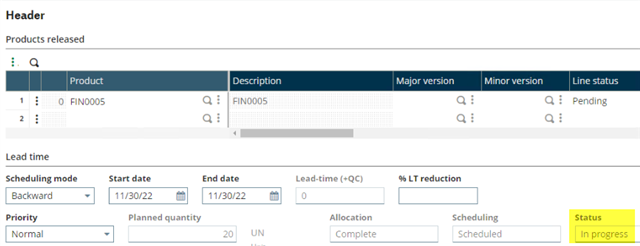

In progress – when the material is issued.

In progress – when the operation is tracked.

In progress – partial receiving of the finished goods.

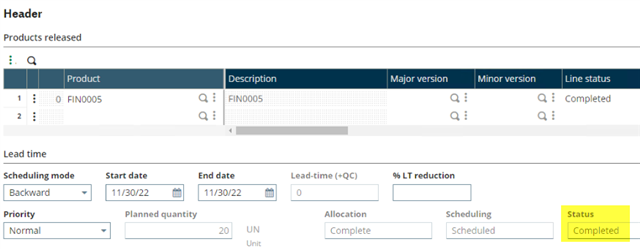

Completed - once the finished good is received and no more remains. Also, the status will default to Completed if the work order is closed but no cost calculation has been done on it yet.

The WO status should transition to Completed when the following conditions in the MFGHEAD table are true:

Expected number of operations to track = actual number of operations tracked

[F:MFG] OPECLENBR = [F:MFG] OPELINNBR (Operations)

Expected number of materials to track = actual number of materials tracked

[F:MFG] MATCLENBR = [F:MFG] MATLINNBR (Materials)

Expected number of finished goods to track = actual number of finished goods tracked

[F:MFG] ITMCLENBR = [F:MFG] ITMLINNBR (Finished Goods)

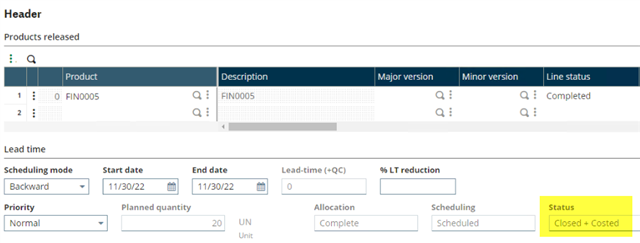

When the work order is closed, the values in the MFGHEAD table will update and when the work order is finalized (WIP Finalization), the status should change to Closed + Costed.

Closed + Costed – When the work order is closed, and production cost calculation is processed.