Hello everyone

I need a small assistance please

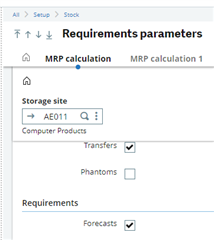

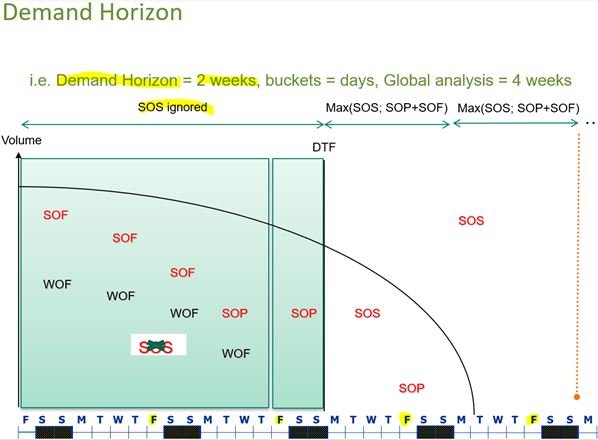

I want MRP to consider the first 4 months as firm sales orders and ignore forecasts in those months and then consider forecasts for month 5 onwards . What I noticed is that the MRP did not consider the forecast in the calculations for purchasing any components .. which is weird ?

I put FOH =4 , POH =4

any ideas please