Put-away plan functionality is available to plan a stock change from a ‘dock’ location category into another location category. For example internal location.

During a purchase receipt, miscellaneous receipt, delivery return and loan return we can receive the inventory into a dock location in order to receive the stock quickly and mark it as received.

The stock received at dock then needs to be effectively put away. This is the purpose of the put-away plan function.

This is a workbench used by warehouse employees to select and display stocks awaiting storage: system calculates the potentially missing stock information of the lines, as well as the location where the stock should be put away according to the management rule of the original receipt movement (miscellaneous receipt, receipt, delivery return, etc.).

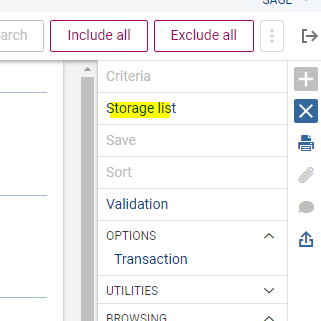

The user assigns a storage list number to a group of lines in the process of being put away.

This list can be printed and used to support the physical movement of stock items and then recalled to validate put-away movements in the system.

Validating put-away on the system means carrying out intrasite location changes specified in the put-away plan and therefore updating the original receipt note with the final stock information entered upon put-away.

Function name: FUNSSL

Path: Stock, Internal transactions, Put-away plan

A storage plan put-away function is also available in VT (virtual terminal) mode.

Function name: VXASY

Path: ADCs, Stock, Put-away plan putaway

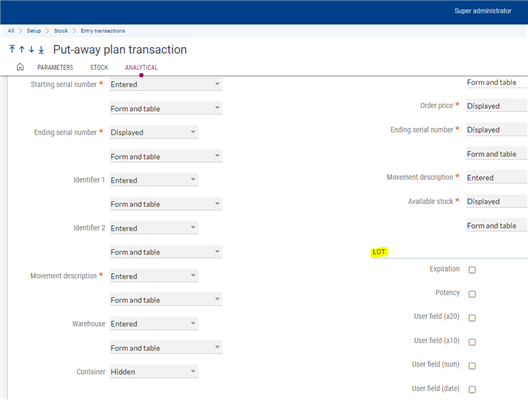

Create a new entry transaction under Setup, Stock, Entry transactions, Put-away plans.

It is used to perform stock changes from the lists of the put-away plan and automatically launch label prints.

Once you validated the document by clicking OK, you can no longer access it.

Prerequisites:

Following activity codes may have an impact on the way the function operates:

- SLO: Management by sub-lots (Calculated value/dependent activity code)

- ECC: Product version management

- EMP: location management

- LOT: Lot management

- LPN: Internal container management

- PAL: Stock identifiers

- SER: Serial number management

- WRH: Warehouse management

- ENW: No of stock lines per document (sizing)

Entry transaction:

There are 2 standard entry transactions available for the put-away plan

- RGP

- WRH

General parameters:

The following general parameters may change the way the function works;

- WIPSTOLOCK Blocked quantities being put away (STO/MIS) the general setup "Blocked quantities being put away" is used to plan that the stock waiting to be put away and taken into account in the put-away list will be locked and therefore cannot be used by other functions.

- Yes – Issue movement is not authorized but a global allocation is possible.

- No – The stock waiting to be put away are taken into account in the put-away list and can be used and also allocated. As a result the stock to be put away is adjusted.

- FEALOTLEV Characteristic level of lot (STO/MIS)

- Lot – The information in the lot addition are managed at the lot level: Any entry and or modification to the lot information is transferred to all the sub-lots of this lot.

- Sub-lot – The information in the Lot addition are managed at the level of each sub-lots.

- Information concerned are the following; Title, Expiry ref., expiry lead-time, expiry date, UBD coefficient, expiry date, new control lead-time, new control date, user fields 1 – 4.

Utilities:

Recovery of put-away plan:

Under Stock, Utilities, Put-away plan resync

The resynchronization processing of the put-away plan is used to filter the records in the STOSRG for which STAFLG (status) field has an inappropriate value.

STAFLG = 1 Waiting put-away.

The objective of this resync utility is thus to correct the records in STOSRG where the STAFLG = 2 (Put-away plan).

i.e. it verifies that no records exist in STOSRG where STAFLG = 2 due to an error.

It also verifies the coherence between STOSRG (storage), STOSRGW (storage details) and TABWIPSTO (locked stock quantities).

If other users are connected and working in the put-away plan, a warning message will be displayed when launching FUNSYNSRG.

Reports:

There are 2 standard reports that can be used for this

- PRTSCR: Screen print

- STOSRG: Storage list - use the printer icon

For additional information please refer to function help.

Let's look at an example;

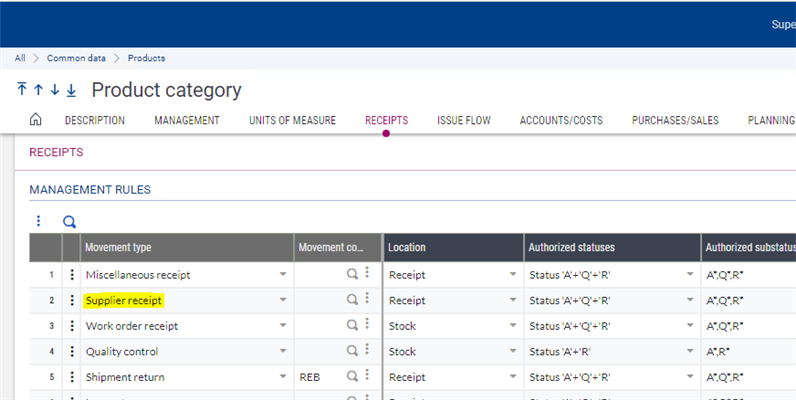

Prior to generating a supplier receipt I would like to talk about the setup on the product-site record and on the product category.

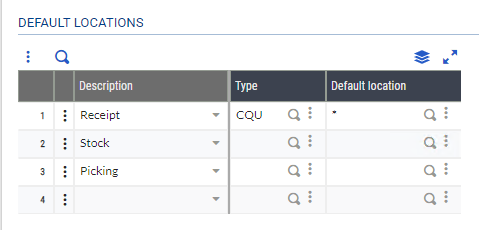

As you know we can setup default location type and locations on the product-site record.

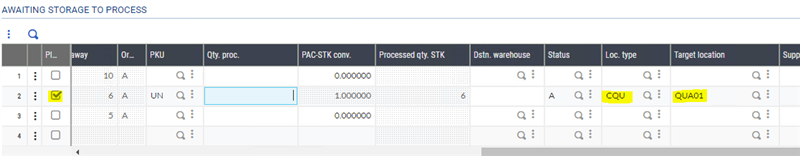

- In Common data, Products, Product-site, Default locations I am going to use "CQU" as the default location type for location category "Receipt".

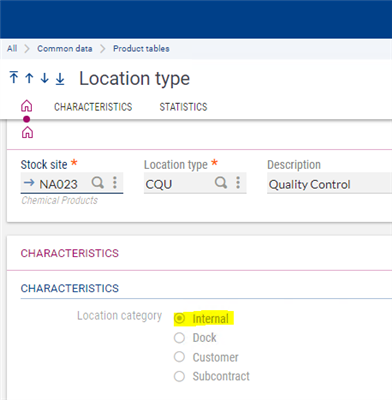

Location type CQU is an internal location

Under product category receipts tab note, the "supplier receipt" movement type has the location column set to "Receipt".

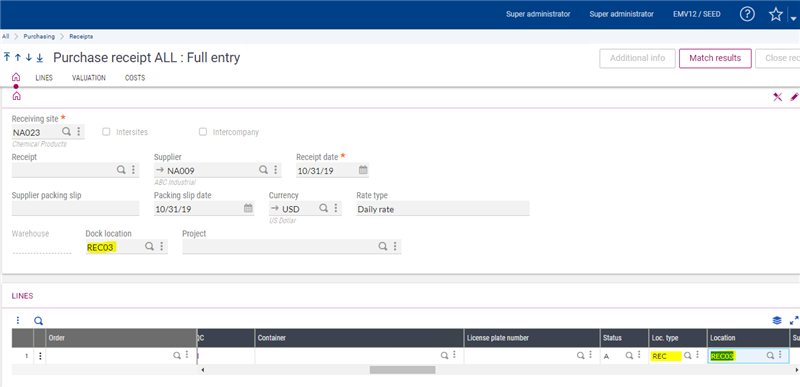

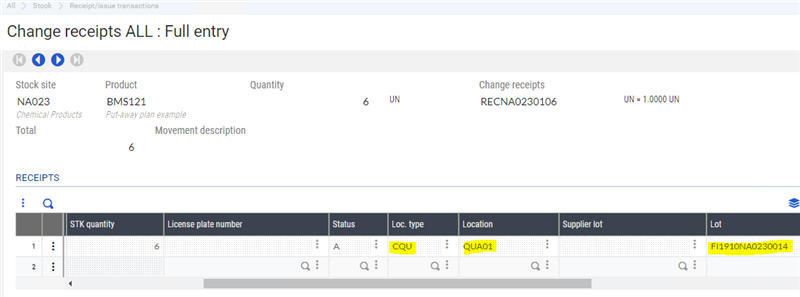

Now lets create a supplier receipt selecting a dock location.

Notice, when you receive inventory into a dock location the receipt lines also get the same location assigned to the dock location.

This is the preferred method when receiving the inventory into a dock location.

Once you created the receipt now we can put-away the inventory into proper locations based on the setup of the product.

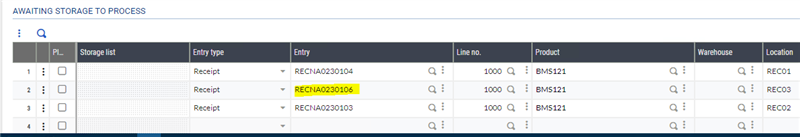

Under stock, internal transactions put-away plan, select the entry transaction and search the receipt transaction.

Notice, on receipt RECNA0230106 the location is set to REC03 which is the dock location specified on the receipt.

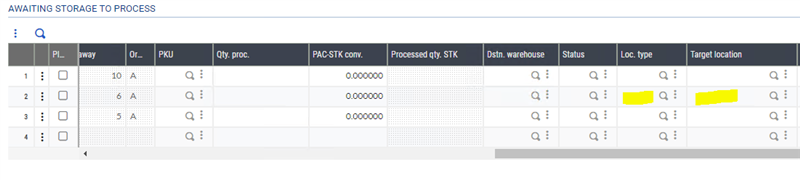

Target location type and location are empty

Now select the line and notice, the target location get filled with the default location on the product-site record.

Enter the quantity to process and tab out of the line and use the action icon to select the storage list and save the changes or use the validate button to complete the process.

Once you validated the transaction, in supplier receipts the line will have the new location.

I hope this article is useful to understand the put-away plan process in Sage X3.