Currently MRP doesn't replan the material requirements of a replanned work order or subcontract order. Thanks to the new parameter "Replan material requirements". With this new parameter MRP now replans the material requirements of a replanned work order or subcontract order.

Lets take a look at the issue and the solution below;

Issue:

When a new demand is added to an existing sales order, MRP is just indicating to increase the quantity on the existing work order. However, it doesn't suggest to increase the quantity on the existing purchase order suggestions (POS) for its components.

In other words, you have a firm sales order (SOF) for a manufactured item, when you run MRP it will generate a work order suggestion (WOS). Next you convert the WOS to a firm work order (WOF). Do the same for the purchased components, and then convert the POS into POF. Create another SO or add another line for this same manufactured item to the existing SO. Run MRP, notice the system will suggest to increase the qty on an existing WO. However, it doesn’t ask you to increase the qty on an existing PO for the components. Therefore, it is difficult to say what needs to be bought.

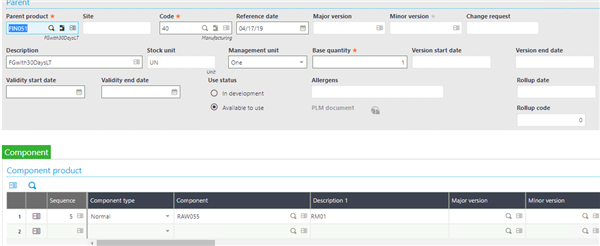

- GESBODP: Create a simple production BOM and assign a routing to it.

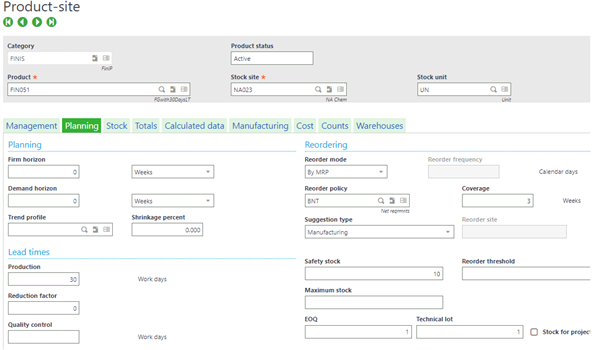

- GESITF: Product -site record Manufactured product, suggestion type = Manufactured, safety stock = 10, Production LT 30 days.

- Product-site record Raw material

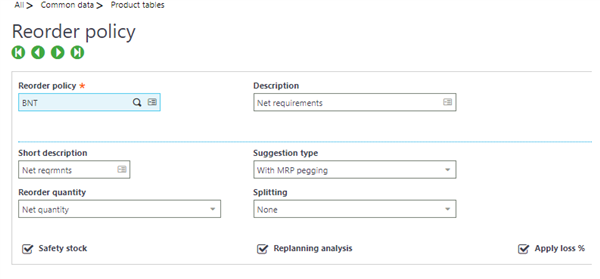

- Reorder policy: Net requirements

- GESSOH: Generate a SO for 5 units.

- Run MRP

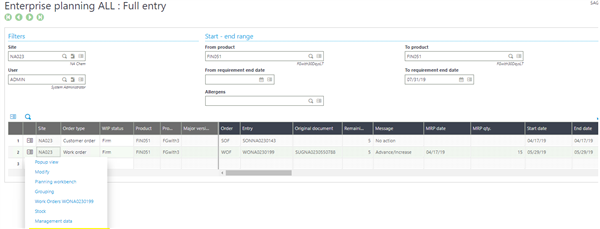

- FUNGBENCH: Enterprise Planning workbench select the finished product and select the "Associated orders to zoom" option using the action icon on the line.

- Select the raw material

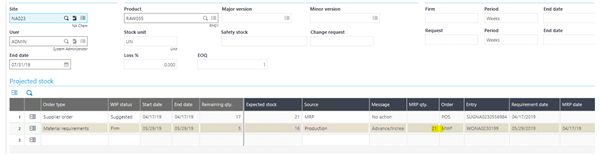

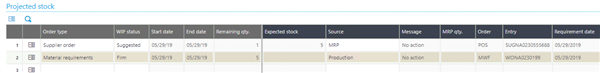

- Planning workbench, supplier order suggestion (POS) for 1 and a materials requirement firm (MWF) for 5 quantities.

- GESSOH: on the SO increase the quantity by inserting a new line.

- Sales order quantity increased by 6

- Run MRP

- In Enterprise planning workbench replanned SO did not replan the materials

- Finished good/parent items new MRP quantity = 21 (Original quantity 5, new quantity 6, Safety stock 10)

- Material has not been replanned.

Solution:

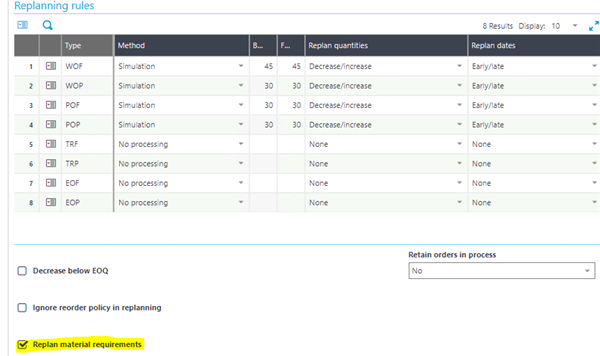

- A new parameter "Replan material requirements" has been added on requirements parameters screen, in Tabs MRP Calculation 1 and MPS Calculation 2.

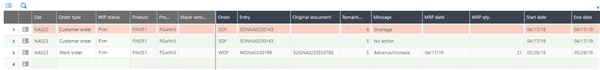

- With this new parameter MRP now replans the material requirements of a replanned work order or subcontract order.

- If the WO firm or planned are replanned according to the replanning rules defined on the Requirements Parameters, then all material requirements will be also replanned.

- Like this, we can have a good consistency between the replaning message on the product released requirement and the material requirements linked.

- New check box in Setup, Stock, Requirements parameters, MRP calculation 1 and MPS calculation 1 tab is introduced in v11.0.13 with the following fixes 4982 and 5019 (request # 128657).

- Not available in versions prior to v11.

- Select the "Replan material requirements" check box and save the changes.

- Run MRP and notice the material requirements (MWF) line MRP qty. is 21 and the MRP message is "Advance/Increase" - Expected behavior.