In Manufacturing, we all know that we can use the Production tracking function "GESMTK" to track work orders one at a time. However, what if we want to track more than one work order, or let’s say we want to mass track work orders with their operations, materials, and productions! Is that even possible?

In Sage X3, Production tracking block, there is a function called Managing the tracking plans "FUNBENPLT" that allows mass track of work orders. However, this function is for one site at a time with multiple work orders. Also, the work order must be in a “Firm” status to be tracked.

This function has several actions to process:

Time tracking

Material tracking

Manufacturing tracking

Re-integration tracking

And technical sheet tracking

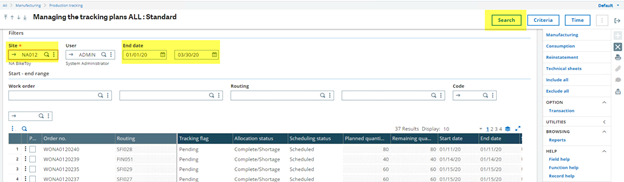

When launching the function, the Site is mandatory, and the End date range can be entered to limit the number of work orders to display. Once the date range is entered, you can click Search to let the system search for the firm work orders that are ready to be tracked or you can enter a Start and end range of work orders.

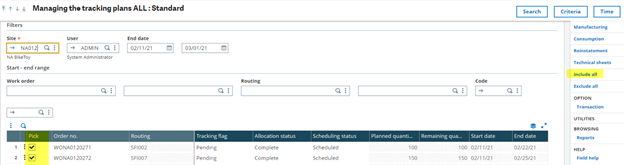

Once the work orders are displayed, you can click “Include all” from the Right panel to select all the work orders or you can select them by checking the box in the Pick column manually.

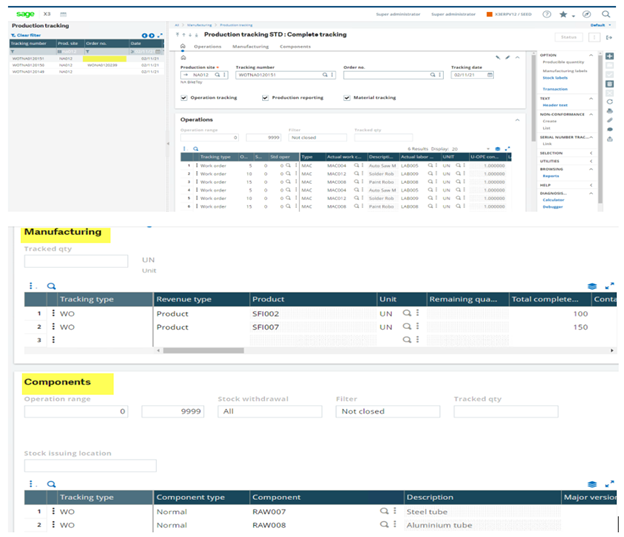

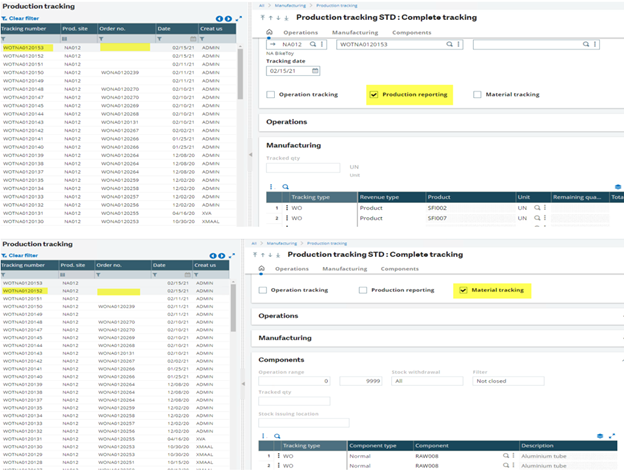

After the WOs are selected, if you are ready to track time, materials and finished goods altogether and only generate one production tracking for all work orders, clicking the Time button will accomplish that and you can check the results by going to Manufacturing, Production tracking, Production tracking and looking up the transaction. In the Production tracking function, you will notice that in the Left list, the Order no. will be blank because we tracked more than one work order on the same production. However, when it is time to close the work order, each work order will be closed separate from the other.

If you need to track more than one work order but produce separate production tracking for each type (material, operation, manufacturing), you can do so by processing Consumption or Manufacturing first, then track the Time.

Top Comments

-

Kevin_Coulter

-

Cancel

-

Vote Up

+2

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

Comment-

Kevin_Coulter

-

Cancel

-

Vote Up

+2

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

Children