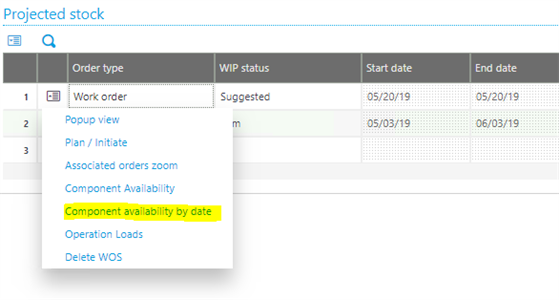

In the planning workbench under projected stock grid, you can view the material first availability date, first availability quantity, etc. by selecting the action icon, contextual menu "Component availability by date".

In V11.0.13 and U9.0.11, this contextual menu was redesigned to have the following information, such as the requirement quantity, first availability date, first availability quantity and requirement date quantity in the provisional availability screen. Additionally, some of the columns were renamed and one column was removed.

First availability date:

- Earliest date that the requirement quantity can be satisfied.

- Accumulated quantity (stock + supply – demands) greater than equal to the requirement quantity.

First availability quantity

- Accumulated quantity (stock + supply – demands) greater than equal to the requirement quantity.

Requirement date quantity

- Quantity equals to accumulated stock (stock + supply - demand) at the requirement date for MWS, MWP, MWF.

Or delivery date quantity for the quantity equal to accumulated stock (stock + supply - demand) at the delivery date for MSS, MSP, and MSF (subcontract).

Note, available at date - removed.

Let’s look at some scenarios to understand how these fields get populated;

Prerequisites:

- At least one existing finished product, reorder mode = MRP, reorder policy = BNT (net requirements), suggestion types = Manufacturing, coverage = 3 weeks.

- An existing and valid BOM for the manufactured item includes component.

- An existing and valid routing for manufactured product.

- Components used in the above BOM have purchase LT = 50 days, and reorder mode = MRP, reorder policy = BNT, suggestion types = Purchase.

- MRP requirements parameters are defined.

Scenario 1: Zero available stock

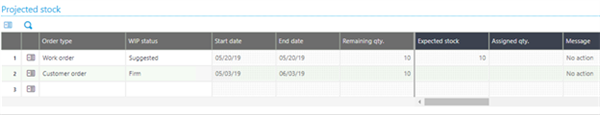

1. SOF with the required delivery date = 06/03/19, Quantity = 10

2. Run MRP

3. In the Planning workbench (FUNDBENCH) select the site, product and click search.

- Sales order firm - end date 06/03/19

- Work order suggestion - end date 05/20/19.

4. Select the WOS line and click the action icon to select the contextual menu “Component availability by date”.

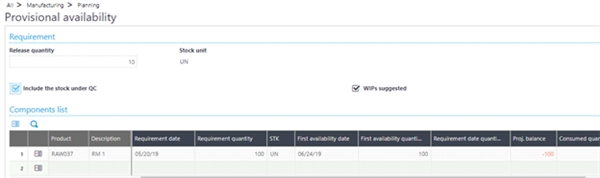

5. In Provisional availability screen you will see the following information;

a) Product code and description

b) Requirement date = WO start date = 05/20/19

c) Requirement quantity (raw materials) = 100

d) First availability date = today’s date + 50 (purchase LT – calendar days) = 06/24/19

e) First availability quantity = 100

f) Requirement date quantity = 0

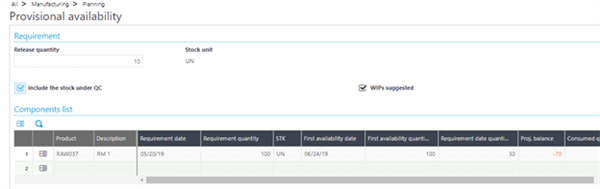

Scenario 2: Add stock to material.

1. Receive in quantity of 30

2. Run MRP

3. Planning workbench, Component availability by date

a) Requirement date = WO start date = 05/20/19

b) Requirement quantity = 100

c) First availability date = 06/24/19

d) First availability quantity = 100

e) Requirement date quantity = 30

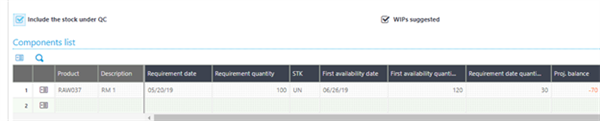

Scenario 3: Create a purchase order.

1. POF, Qty = 20, Expected receipt date = 06/26/19 (today’s date + 50 purchase LT)

2. Run MRP

3. Planning workbench, Component availability by date

a) Requirement date = 05/20/19

b) Requirement quantity = 100

c) First availability date = 06/26/19

d) First availability quantity = 120

e) Requirement date quantity = 30