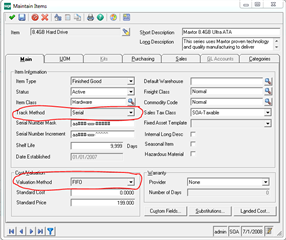

Inventory items can be tracked by lot or individual serial number or can be both lot and serial tracked.

- Serial - a unique number assigned to a single piece

- Lot - a unique ID assigned to a homogeneous quantity of material

- Both - use both serial and lot numbers

- Negative quantity is not allowed for serial, lot or both tracked items

- Back Flush in manufacturing module cannot be used for the raw materials that use serial, lot or both tracking method in Maintain Routing - tracked items must be issued to work order

- Actual Costing Method needs to use serial, lot or both tracking methods. If Track Method is None then Valuation Method cannot be Actual

- Items tracked by serial number, lot number, or both can use any Valuation Method (Standard, Average, FIFO, LIFO, or Actual)

- Tracking method CANNOT be changed after the item is saved

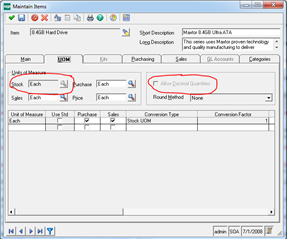

- If an item is Serial or Both tracked 'Allow Decimal Quantities' checkbox is disabled.

- Track Method defaults to none and remains disabled for all Non Inventory Items and BTO Kits.

- For serial and ‘both’ tracked items, a user may define a format mask that will be validated when serial numbers are entered in the system (optional).his serial number mask defaults from module options

- The mask is required if the user wants to set up an increment rule

- Only numeric values may be incremented