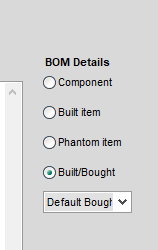

Hi, can someone answer the question or whether a stock item that is listed as a built part and has a bom attached to it, which has no operations or components because its actually a bought part, would affect anything in MRP if its listed as a subassembly in another bom that has a work order created for it?

I have noticed that we have nearly 600 items that are in this exact state and I am trying work out if MRP will create more work when it doesnt need to, due to the item being "labelled" wrong?

Any ideas?